PowerResinGCC

DARK

DARK

Couldn't load pickup availability

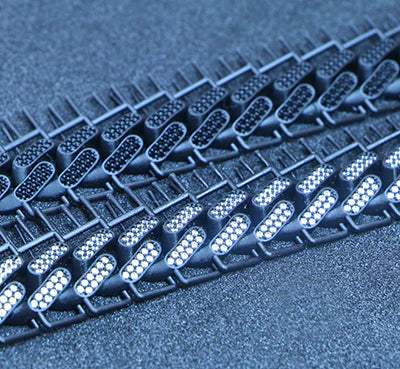

PowerResins Dark has been developed specifically for direct casting of jewelry with high details. It provides perfect casting quality combined with very sharp printing abilities and easy to set stones. Perfect printing properties with sharp details suitable for jewelry with micro-pave prongs, engraving, highly detailed figures or filigree jewelry designs.

- Smooth surface quality

- Shrinkage rate is %3

- Suitable for 365nm, 385nm and 405nm wavelenght 3D printers

- Find here printing parameters for DLP and LCD printers

Product Description

Product Features

- Smooth surface quality

- Shrinkage rate is %3

- Suitable for 365nm, 385nm and 405nm wavelenght 3D printers

- Find here printing parameters for DLP and LCD printers

Post Process

1- Washing

After the printing is completed, wash the part as attached to the building plate with ethyl alcohol (>%90) or isopropyl alcohol (>%90) for 5 minutes. Make sure that alcohol covers the part entirely when washing. Do not over-wash, it may cause deterioration in dimensions of the part.

2- Drying

Use air-compressor to dry the washed part. Make sure that the part is dry and uncured resin is cleaned up completely. If still uncured resin left on the part, wash it with fresh alcohol and dry again.

3- Part Removal

Remove the printed part from the building plate using a scraping tool. Be very careful not to damage your hand and the model.

4- No need post UV curing! Enjoy your casting.

Storage Conditions

Store the PowerResins Burn bottle in dark and moisture free place at room temperature (20-24 °C).

Do not forget shaking the resin well before use.

-

SHARP DETAILS

Perfect printing quality with sharp details.

-

EASY TO SET STONES

Easily set stones directly on printed model before casting.

-

EASY TO CAST

Easily cast your jewelry models with Optima prestige, Omnicast, Ransom & Randolph.

-

NO NEED POST UV CURING

After printing simply wash and dry yet ready to be casted.